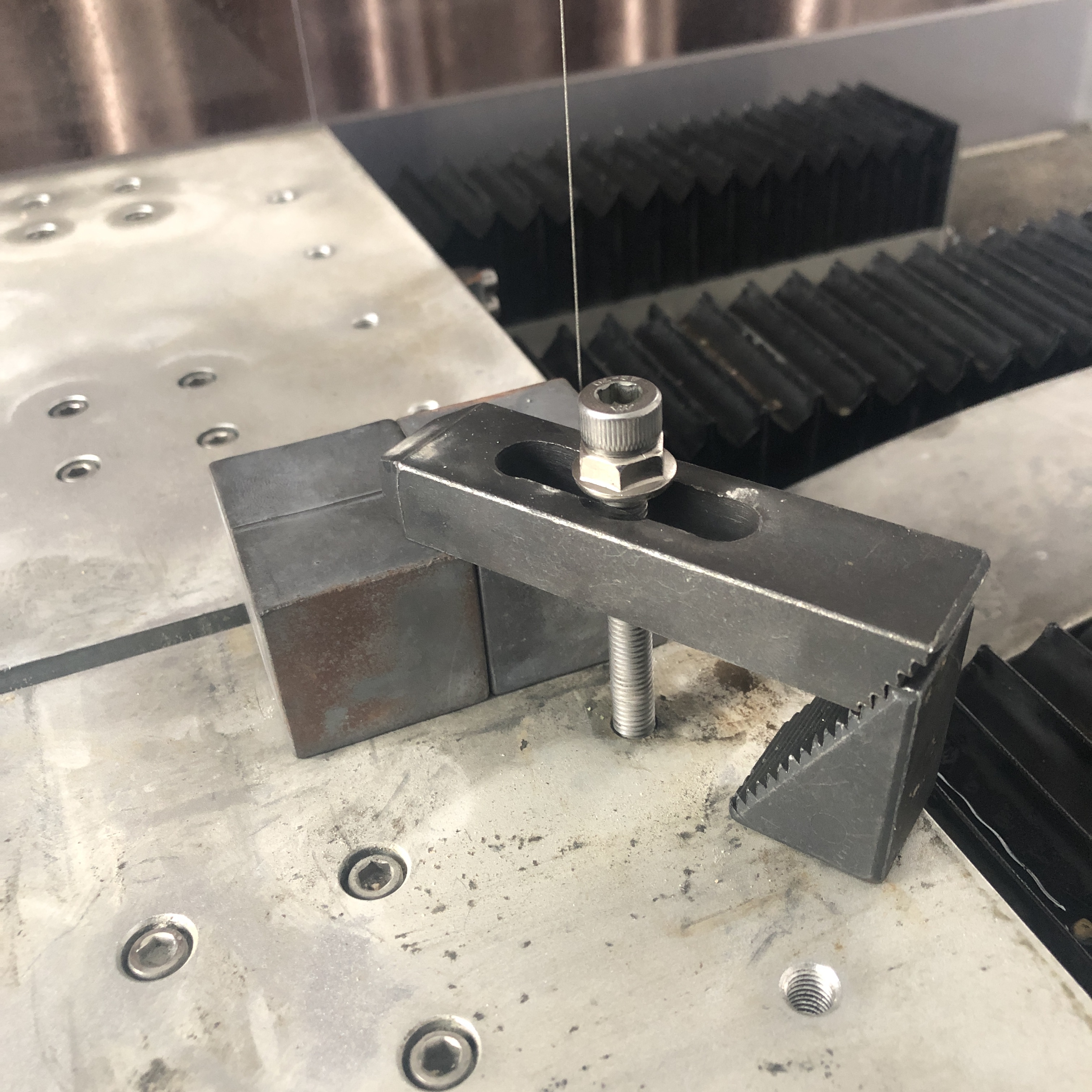

Magnetic NdFeB Cutting with Diamond Wire Loop Saw

The advantages of high energy density make NdFeB permanent magnet materials widely used in modern industrial and electronic technology. So the Magnetic NdFeB Cutting method is very important. Diamond wire loop saw balance the high cutting efficiency 35m/s-60m/s and the great surface finish.

Cutting material: NdFeB 5.8cm*3.8cm*3.8cm

Cutting linear speed: 42m/s

Feedrate: 5mm/min

Wet cutting

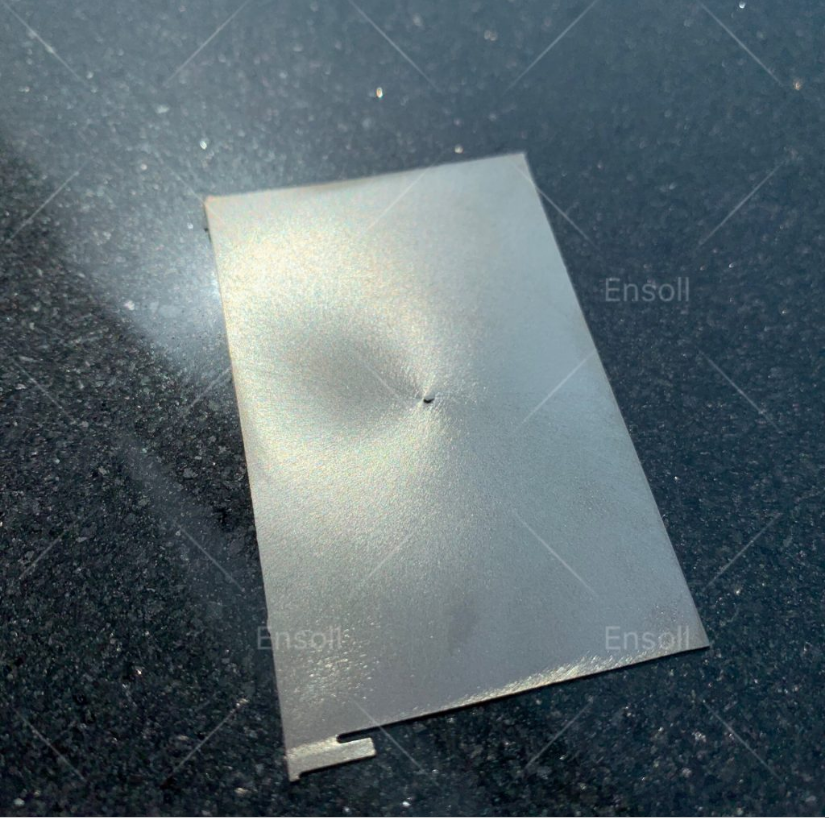

Cutting results: Cutting thickness 0.34mm

Cutting time: The whole process just need 7 mins.

Due to the high hardness of NdFeB, it is very hard for the cutting for the common cutting tools, usually the feedrate is 3mm/min, but the endless diamond wire loop feedrate could be up to 5mm/min, greatly improved the cutting efficiency.

CATEGORIES

- Tire Section Cutting Wire

- Photovoltaic Silicon Cutting

- Sapphire Cutting

- Crystal Cutting

- Glass Quartz Cutting

- Metal Cutting

- Graphite Cutting Wire Saw

- Cearamic Cutting with Diamond Wire Loop

- Magnetic NdFeB Cutting with Diamond Wire Loop Saw

- Samples Seperation Cutting

- eggshell cutting by endless diamond wire loop

LATEST NEWS

CONTACT US

Contact: Ensoll Tools Technology CO.,LTD

Phone: +86-19937798228

Tel: +86-371-56622880

Email: yuansu@yuansutools.com

Add: Liandong U Valley Enterprise Port,Building 1, 3rd Floor, Lotus Street, High-tech Zone, Zhengzhou,China