Diamond Wire Loops ties wire

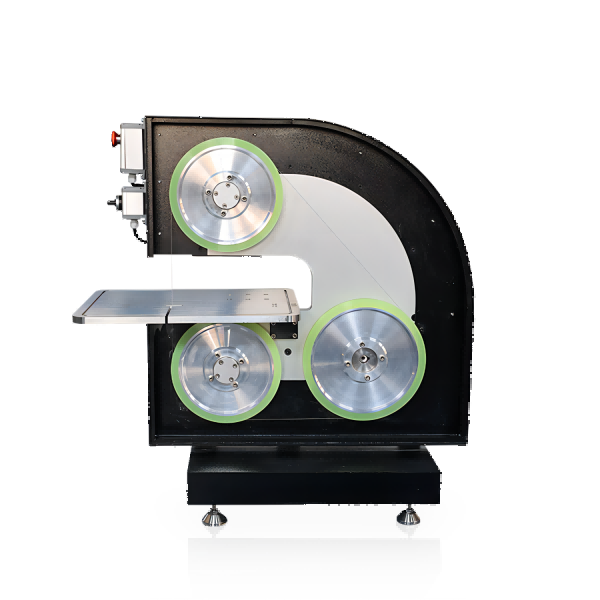

EST200-2T Benchtop Endless Wire Saw Machine

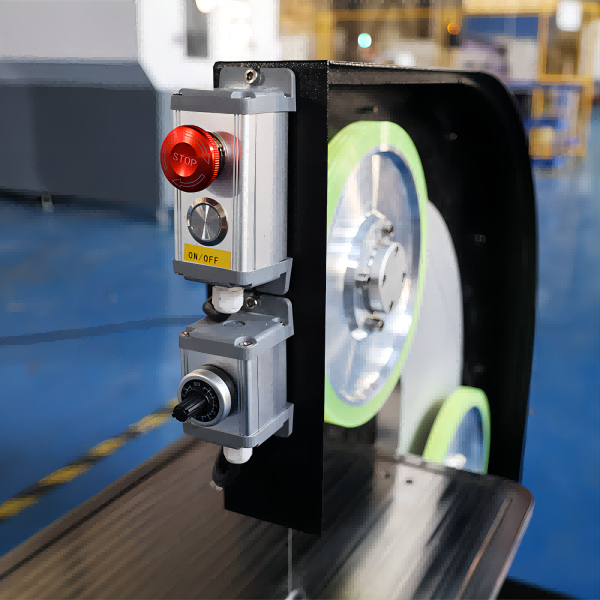

- Fast cutting speed

- Compact model

- Easy to operate

- cutting machine

- Product description: EST200-2T Benchtop Endless Wire Saw Machine is suitable to cut almost all kinds of material such as glass, rock, jade, silicon, ceramics and so on, especially for cutting high-value hard brittle mater

EST200-2T produced by Zhengzhou Insoll Tools,known as endless diamond wire cutting machine(Gantry type), uses diamond wire loop as cutting tool. The linear speed is 3 to 4 times of traditional wire cutting. It’s cutting speed is fast and has very simple operation and small machine size.

Our products can be widely used in many fields,The specific parameters and application specifications are as follows

Cutting Sample Spec

Sample Size : within 200mmX200mmX190mm (L*W*H)

Machine Spec

|

Specification |

Specific parameter |

|

Machine Size |

L7000mm X W610mm X H700mm |

|

Motor power of sliding table |

Y axis 400w Z axis 400 w |

|

Spindle motor power |

370w |

|

Machine weight |

120 KG |

|

Feed speed |

1-1000 mm/min |

|

Linear speed |

10-30 m/s |

|

Wire Length |

1420 mm |

|

Loading capacity |

400 kg |

The equipment equipment frame is steel and aluminium alloy , with simple structure it’s beautiful and practical.

Why choose our products?

Zhengzhou Ensoll Tools is a high-tech enterprise specializing in the research and production of Endless diamond wires & Equipment.The company has nearly one hundred patents. It is TOP leader company to start mass production of endless diamond wire and adapt it to the large-scale cutting needs of different industries.

Compared to traditional cutting equipment,Our product has the following advantages:

1、Higher line speed, faster cutting speed

2、Safe and easy to replace wire

3、Less edge breakage

4、Less cutting loss

5、No commutation grain, high cutting quality

|

Processing time —— Save 60% cutting time Endless diamond wire cutting by one-way movement under high cutting linear speed, the cutting efficiency was highly improved. |

|

Cutting quality——improved 50% Ensoll diamond wire use patent tech to coat diamond abrasive to the core wire , total thickness variation is small .the cutting surface have less wire marks and less possiblity to chip. |

|

Labor cost——One worker can operate 3 to 5 machines Endless wire saw don’t need difficult winding job,it’s very easy to operate. |

|

Cutting cost ——Save 60% Machine cost is much less than traditional ones, and One loop can cut more than 160 times at 4-6 min per cut ( 9 inch silicon) ;125 times at 6-9 min per cut (10 inch silicon); 100 times at 7-10 min per cut (12 inch silicon). |

If you have a demand for cutting superhard materials, such as sapphire, monocrystalline silicon, photovoltaic glass, semiconductors, etc., or pursue high section quality, you may want to take a look at our endless diamond wire cutting equipment and contact us quickly!

LATEST NEWS

CONTACT US

Contact: Ensoll Tools Technology CO.,LTD

Phone: +86-19937798228

Tel: +86-371-56622880

Email: yuansu@yuansutools.com

Add: Liandong U Valley Enterprise Port,Building 1, 3rd Floor, Lotus Street, High-tech Zone, Zhengzhou,China